Galvanis Steel Interlocked Oval Pipe Roll Forming Mesin

Berspesialisasi untuk saluran listrik & saluran kabel

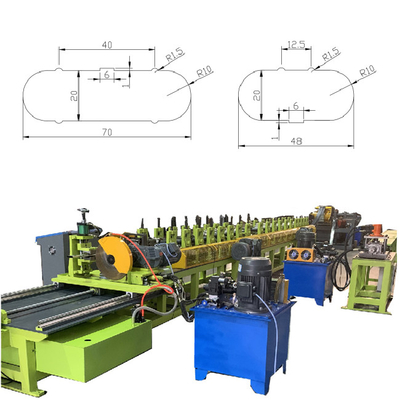

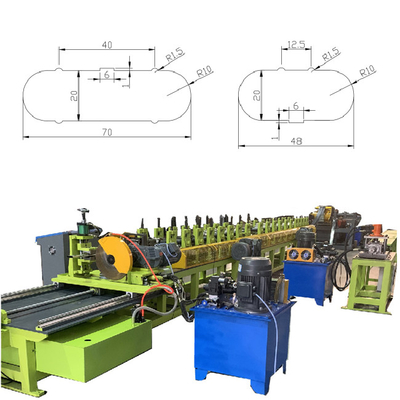

KitaMesin Membentuk Roll Pipe Oval Terpadudidesain untuk presisi dan efisiensi dalam produksi massal pipa oval dinding tipis untuk saluran listrik atau saluran kabel. Menggunakan prinsip roll forming,Hal ini menciptakan tabung oval saling terkunci (tidak perlu pengelasan untuk bahan tipis) dan mengintegrasikan fungsi kunci seperti leher untuk koneksi tabung mudah, struktur pipa tanpa jahitan.

Aplikasi utama: Pipa oval untuk saluran listrik & saluran kabel

Pipa-pipa oval yang saling terkunci yang dihasilkan oleh mesin ini melayani dua peran penting dalam sistem listrik:

- Saluran listrik:Lindungi kabel listrik dari kerusakan eksternal (misalnya, benturan, kelembaban) dengan struktur tertutup dan terkunci yang memastikan keamanan jangka panjang.

- Saluran kabel listrik:Mengorganisir dan mengarahkan kabel di lingkungan industri atau komersial, memanfaatkan bentuk oval untuk instalasi hemat ruang dan akses mudah.

Kami telah menyiapkan profil gambar rinci dari tabung oval untuk referensi Anda hubungi kami untuk memeriksa apakah dimensi sejajar dengan kebutuhan proyek listrik Anda.

Konfigurasi Mesin Lengkap: Dari Decoiling ke Pipe Finished

Mesin Forming Pipe Roll Oval Interlocked mengintegrasikan semua komponen yang diperlukan untuk produksi pipa oval ujung ke ujung:

- 3TON Decoiler manual:Membuka gulungan bahan baku (baja galvanis atau pracat) secara konstan, memberikan pasokan bahan yang stabil.

- Unit makan:Mengontrol kecepatan dan keselarasan pakan bahan baku, dengan dukungan operasi manual untuk penyesuaian yang mudah.

- Sistem pendingin:Mencegah overheating rol dan bahan selama pembentukan, melindungi komponen mesin.

- Sistem pembentuk gulung:Jantung mesin, membentuk lembaran logam datar menjadi profil oval melalui rol presisi dengan jahitan terjalin.

- Sistem Transmisi:Mengemudi roll membentuk dan satuan makan secara sinkron, menjaga kecepatan membentuk seragam.

- Sistem pemotongan:Memotong pipa oval yang sudah selesai ke panjang yang Anda inginkan, memastikan dimensi yang konsisten.

- Sistem kontrol:Menentralisasi operasi semua komponen, menyederhanakan penyesuaian parameter.

- Rack pendukung yang habis:Mendukung pipa selesai saat mereka keluar dari mesin, mencegah lentur atau kerusakan.

Bahan & Batas Ketebalan yang Kompatibel

| Fitur |

Spesifikasi |

| Bahan yang Cocok |

Baja galvanis atau baja pracat (tahan korosi) |

| Ketebalan Interlock yang berlaku |

0.3-1.2mm (tidak perlu pengelasan) |

| Ketebalan Lebih dari 1,2 mm |

Membutuhkan penggabungan dengan sistem pengelasan atau mesin pembentuk sekunder |

Kustomisasi utama: Desain Perubahan Cepat untuk Pipa Berukuran Berbagai

KitaDesain perubahan cepatmemungkinkan produksi multi-ukuran yang ekonomis:

- Roller dan poros dipasang pada bingkai dasar khusus untuk mengubah ukuran dengan mudah

- Mengurangi investasi dalam komponen bersama duplikat

- Tersedia dalam konfigurasi ekonomi dan berkualitas tinggi

Easy Tube Connection: Necking Machine untuk Overlapping yang Aman

Terintegrasimesin pengikat lehermemungkinkan koneksi tabung tanpa jahitan:

- Mengurangi diameter satu ujung tabung (dengan tulang rusuk penguat) untuk dimasukkan

- Membuat koneksi yang ketat dan aman tanpa pengikat tambahan

- Mempermudah pemasangan dan meningkatkan stabilitas struktur

Lihat Seluruh Proses: Minta Video Kerja

Hubungi kami untuk mengakses video kerja rinci yang menampilkan siklus produksi penuh dari decoiling hingga pipa yang selesai.

Sesuaikan dengan Kebutuhan Anda

Kami dapat menyesuaikan mesin untuk kebutuhan spesifik Anda untuk ukuran pipa, ketebalan bahan, atau kebutuhan produksi.atau pilihan kustomisasi.

Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!  Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!